Robotic Welding System

Designed and installed a robotic welding and drilling system for use in a manufacturing facility while also providing training on robot programming.

Overview

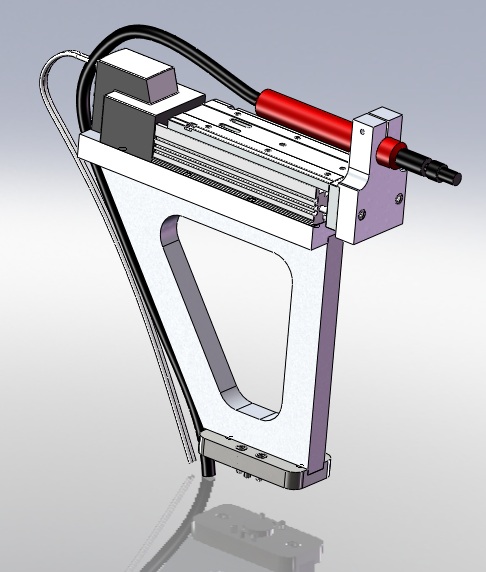

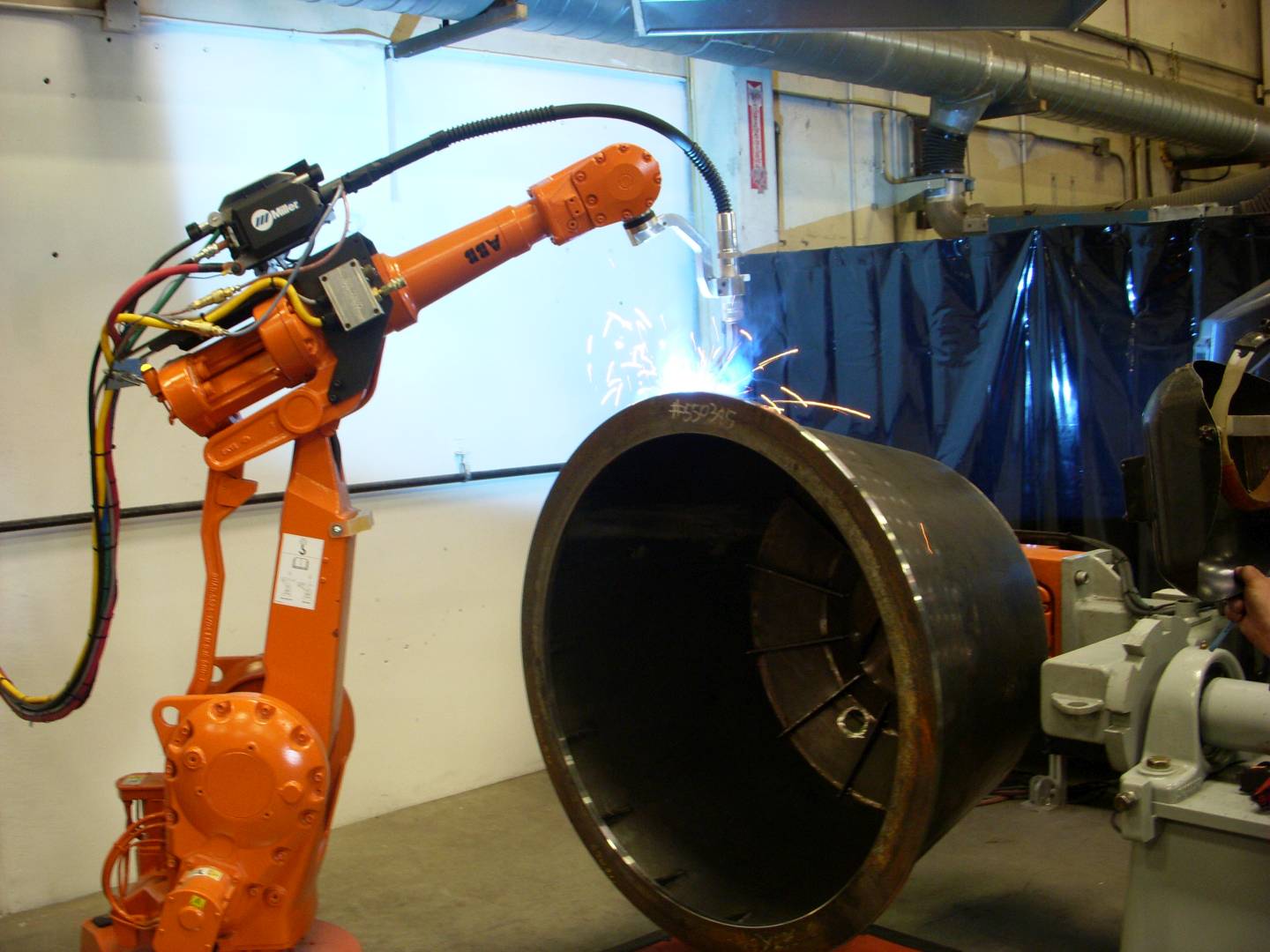

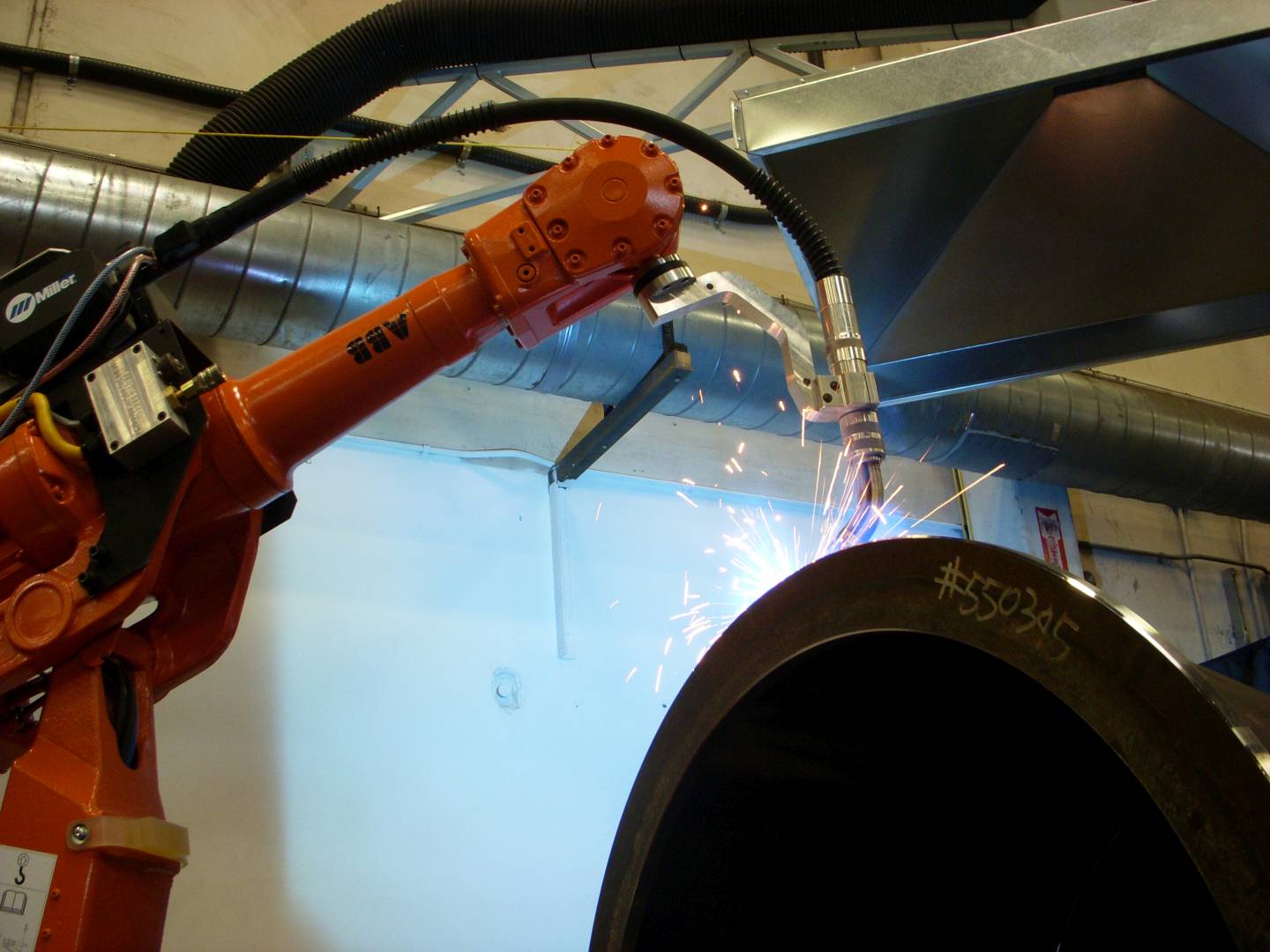

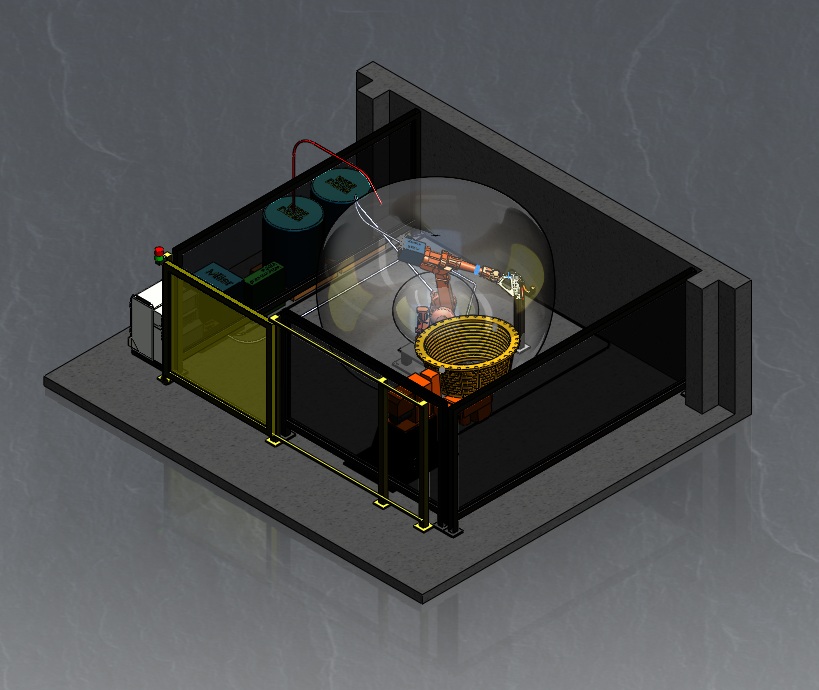

The objective of this project was to create a robotic cell capable of welding and using an alternate attachment for drilling plastic. The welding was using a prepackaged system from ABB robotics while the drilling was a custom solution designed by Williams and White. Training was also to be given to several staff of the customers on both robot programming and the robotic welding process. A custom panel was designed to operate the drilling attachment and it consisted of a PLC and a stepper drive controlling a linear stage with an air powered drill. The entire cell was designed with the Z-434-03 CSA standard in mind for robotic cell installations.

My main responsibilities were to source and design the control for the drilling attachment, program the robot to weld various customer parts, train the customer staff on programming and robotic welding and installation of the electrical components of the cell.

Results

Customer reduced welding time from 8 hours to 1 hour on various parts

Customer staff is now fully trained and able to create custom programs for maximum utilization of their robot

Fully CSA approved design on panel and robotic cell

Easily able to exchange the welding torch with the fully functional drilling attachment

Job

Williams and White

Category

- Industrial Design

- Industrial Robotics

- Industrial Electronics

- Industrial Safety

- ABB Robot Programming

- Welding

- Prototyping